How and Where General Measure’s Checkweigher can be Applied

Publicadas: 2019-08-16 Artigo fonte: 本站

|

Checkweigher, also known as automatic checkweigher, in-motion checkweigher, or weight sorting scale, is a high-speed, high-precision online checkweigher device that can be integrated with various packaging production lines and conveyor systems. It is mainly for products defects identification - whether the weight is qualified, whether there are missing parts in the pack. All the weight data can be collected and archived

In-motion checkweighing has gradually become an indispensable link in modern industrial production, especially in the production of food, medicine, hardware and electric appliance. It can check weight of the product during transferring process, and compare the measured weight with the preset range to reject the unqualified products or distribute the products with different weight ranges to different designated areas.

Our checkweigher consists of an input/output conveyor, a weighing unit and a controller module. The input conveyor can ensure the sufficient space between products by increasing the speed. The weighing unit completes the weight signal collection and sends it to the controller for processing. Then, the output belt is responsible for conveying the measured product to next process.

The specific workflow of General Measure’s checkweigher is as follows:

1. Weighing Preparation

For ensuring there is only one product on the weighing platform each time, the input conveyor speed should be set according to check speed and product spacing requirements.

2. Weighing Process

The weighing unit will estimate whether the inspected item enters the check area according to signals that external photoelectric sensors catches or internal level signals. Then it has the ability to determine when the product can leave the weighing platform by the weighing speed and the length of the conveyor. Sensor sends the weight signals collected during the product on the weighing platform to the controller. While controller will select a stable signal area to process for obtaining the product weight.

3. Sorting Process

When the controller receives the weight signal, the system will compare it with the pre-set weight range for sorting the products, pass or reject. There are several sorting ways. The main types are as follows:

(1) Reject the unqualified product.

(2) Reject products with overweight or underweight respectively, or transport them to the different back-end for further process.

(3) Divide products into different weight categories according to different weight ranges.

4. Report Statistics

The checkweigher has an abundance of reporting functions, which can analyse, save and export the data of each package or total amount of each zone, the number of qualified products, the average value, the standard deviation, the overweight or underweight products amount, and so on.

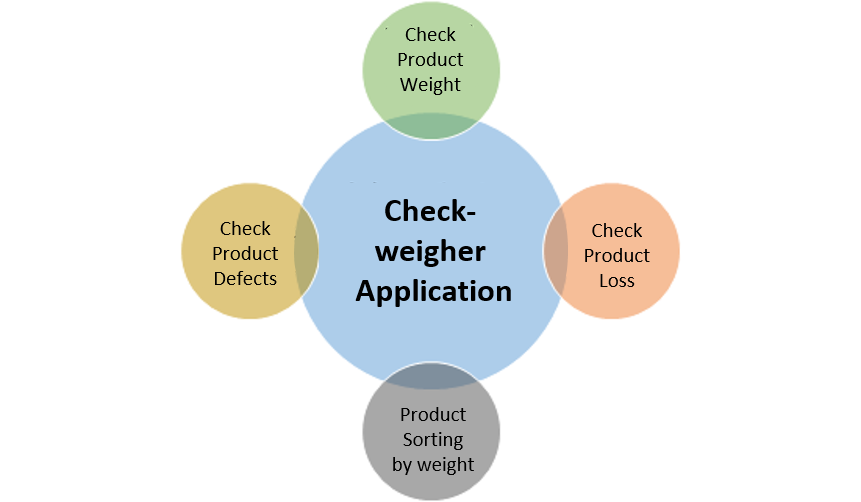

The Application of General Measure’s checkweigher:

Our checkweighers can be applied in a variety of industries, such as food & beverage, pharmaceutical, chemical, plastic, rubber, hardware, electron and other industries.

Mainly used in the following occasions:

|

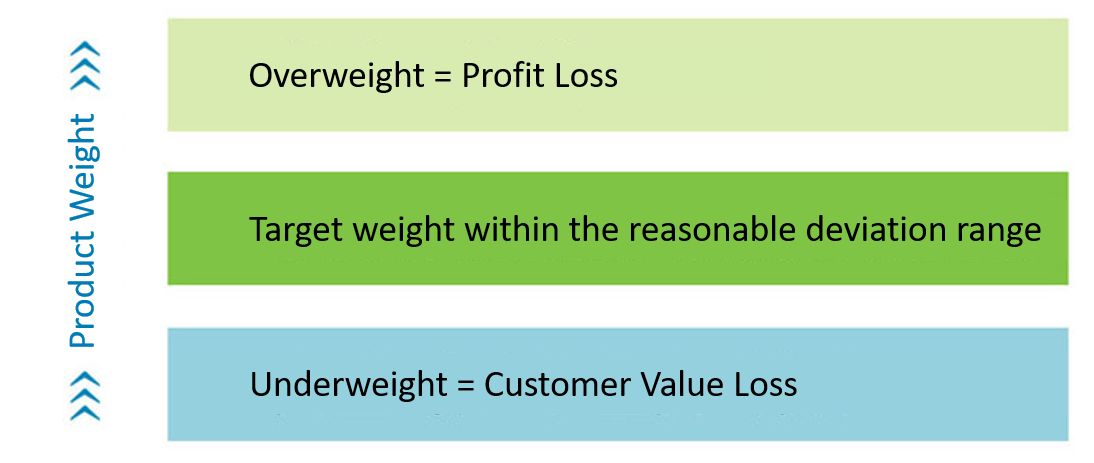

1. Compliance Detection of Product Weight

The weight of the product is detected at the key points during production. Then the unqualified products will be rejected to ensure the product meets the factory requirements. In this case, the interests of both consumers and manufacturers can be protected in the proper way.

|

2. Product Loss Detection

For the detection of product loss, like small packs in a large package (such as a box containing many bottles of softdrink, large bags containing multi-packages). Owing to equipment or human factors, it is inevitable that the product package will not always be perfect. By using checkweigher to identify the missing products, the factory will reduce the customer complains due to the product loss.

3. Product Defects Detection

For notebooks, mobile phones, TVs and other 3C digital products, as well as bicycles, or other hardware products, there are many spare components that need to be packed with the package. However, for various reasons, some parts may be forgotten. In this case, the checkweigher can find out the package of missing parts to enhance the product pass rate.

4. Product Sorting by Category

This function can automatically classify products by weight in high-speed. For example, automatic sorting of seafood, distribution of products of different weight to different areas.

The above applications of checkweigher are just some normal occasion usage. They can also be used in many other industries such as military, printing, and newspapers. For instance, once the United States used the checkweigher to ensure the weight of each bullet, because the weight of bullet can affect the flight path of bullet.