General Measure Quality Improvement

Publicado: 2019-12-25 Artículo fuente: 本站

Background

In a highly competitive market environment, quality is the core strength of any industrial business. Since the development of General Measure Technology for 26 years, it has always focused on quality, no matter products or services. The quality improvement carried out every year is particularly prominent this year.

This work started in July and will last for nine months. The focus is on three departments: Sales&Customer Care, production, and R&D, and each department dominates for three months to make sure the quality of products and services can exceed the previous optimal level.

|

First Step: Sales&Customer Care·Problem Finding & Tools

The first stage is to comprehensively improve products and services quality in the Sales & Customer Care department. To achieve quality improvement, we must first understand the crux of the problem. In this regard, they not only searched and analyzed the historical data: such as statistics of warranty return , maintenance records, analysis of repair problems, technical support records and quality target, etc., but also motivated every sales to contact the client, meanwhile, they seek the assistance of the production to check meeting record, for finding out the common problems and putting forward the solutions. Through the above three methods, four main problems affecting the quality of products and services were summarized from the perspective of Sales & Customer Care:

1. No fault description for returned product

2. The order in wrong type was selected or placed, or the configuration / software version did not match the customer's requirements

3. The failure-free returned products

4. Abnormal Products

Solutions

In response to these issues, the Sales dept. & Customer Care came up with the corresponding solutions and implemented them from September.

1. No fault description for returned products - to strengthen communication with clients. The sales will assist clients to provide fault descriptions for returned products. If there are still no fault description, the customer care will track and take over the case.

2. Order error / mismatch

2.1 Report the problem to the customer service supervisor as soon as possible, and follow the customer-centric principle to reduce the impact on clients;

2.2 Double check each step of the order and delivery process to strengthen the standards;

2.3 Set up training for product selection and conduct various level of professional training for different positions;

2.4 Engineers from R&D assist for products selection to avoid mistakes at the early stag.

3. Failure-free returned product - Provide detailed methods for determining hardware failures and improve the field technical supports.

4. Abnormal products - enhance communication between sales , technical support and clients, provide solutions within 24 hours based on customer-centric principle.

Besides, the sales department conducted a customer satisfaction survey in mid-October which received 90 in overall satisfaction.

Results

Three months’ work of analysis and summary in the sales dept. and customer care has been completed. The implementation of quality improvement has run through our daily work which has also achieved certain good results.

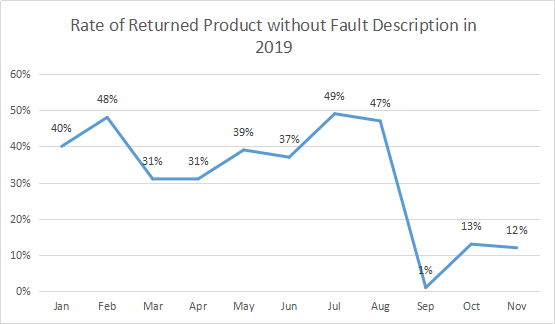

1. Before the quality improvement, the proportion of returned product without fault description is almost 50%. The implementation of improving quality dramatically decrease this rate to 1.4% in September, 10% in October and November respectively. Moreover, the warranty return rate is under 0.2%.

|

2. In September, there were three cases of wrong orders. After the training of product selection, we provided clients with comprehensive product configuration and function information which effectively reduces the wrong orders.

3. After training clients on site by our technical support, the number of non-failure returned products was decreased 20% in October and November.

4. In October, when receiving abnormal feedback from client, the sales manager immediately reported back to the general manager to quickly deal with and reduce clients losses.

No matter at present or in the future, quality has always been the responsibility and pursuit of General Measure. The goal of achieving the ultimate quality in products and services will always take the first place in our daily work.

|