General Measure Packing Scale Test Platform: Setting a New Benchmark in Packaging Testing

Publicado: 2025-04-09 Artículo fuente:

In the field of industrial automation weighing and packaging, the speed and accuracy of packing machine directly determine the packaing production efficiency and product quality. Choosing a high-performance and high-quality packing scale is crucial to packing machine for fast and accurate packaging. But how can we ensure that the performance of the packing filler remains consistent under varying materials and environmental conditions?

With decades of technical accumulation and experience, General Measure has spent a full year gradually building and perfecting a professional packing equipment testing platform tailored specifically for high-speed, high-precision packing scale units.

General Measure packing scale test platform, featuring a 9-meter-high vertical testing tower with 3 independent testing levels, it provides 10 independently operating test stations and simultaneous testing of 5 different types of granular materials. It provides an all-encompassing, professional, high-precision, and efficient testing environment for weighing and packaging applications across various industries—empowering businesses to achieve efficient, stable, and reliable packaging production.

|

Advantages of the General Measure Packaging Test Platform

1. Independent Multi-Station Operation for Enhanced Efficiency

It provides 10 independently operating test stations, allowing 5 different types of free-flowing materials to be tested simultaneously, improving testing efficiency and shortening equipment debugging time.

Multi-weighing-range testing with recheck capabilities enhances weighing accuracy and minimizes errors.

|

|

2. Full-Scope Simulation Covering Multiple Materials

Materials with varying characteristics can be tested concurrently, reducing material switching time and boosting efficiency to fulfill the different industries condition and requests.

The packing scales can be flexibly adjusted testing parameters according to different industries and material types, perfectly adapting to all kinds of free-flowing materials. It simulates diverse test environments to ensure stable performance of packing scales under all scenarios.

|

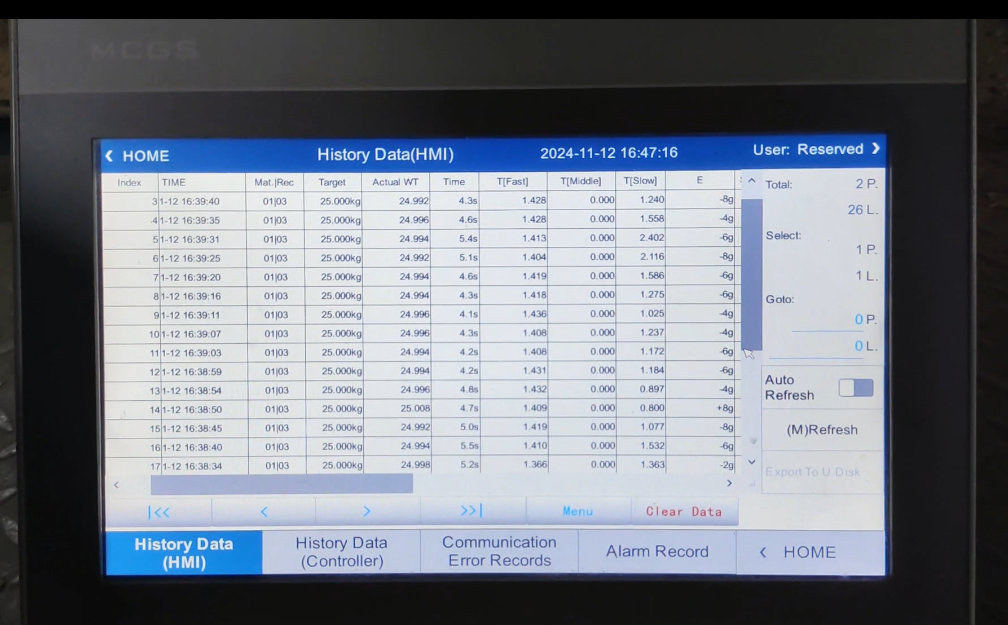

3. Integrated PC-Based Data Acquisition System

Equipped with a PC data acquisition system, the packing scale under testing can continuously collect data via communication ports and stores historical data.

It’s also capable of recording weight curves and providing comprehensive test data, such as accuracy, speed, and stability, ensuring the precision and reliability of every data entry.

|

4. Harsh Environmental Testing for Durability

GM packing scale testing platform can simulate complex environments such as vibration to test the durability and anti-interference capabilities, ensuring stable operation even under harsh conditions.

5. Intelligent Remote Control and Real-Time Monitoring

Real-time visualization of the equipment status on all three levels, with remote access to key data such as weight, speed, and precision.

The system is equipped with smart safety warnings to effectively prevent high-altitude operation risks. Test data is automatically collected and report generation is streamlined, improving both safety and testing efficiency.

General Measure's Professional Packing Test Platform is not only a testament to our production capability but also a commitment to quality. We are dedicated to providing the most professional testing environment for every packing scale, ensuring outstanding performance, stability, and reliability of your packing machine!