CATL Case - Application of Field-bus Indicator (GM8802-PN, GM8802-EIP)

Published: 2019-10-15 Article source: 本站

CATL that is developing rapidly in recent years, is focused on the lithium battery for new energy vehicle. According to statistics on CATL’s official web, their sales volume of power battery systems ranked the top three in global power battery companies for three consecutive years, and at the first place in the world in 2017 (11.84Gwh) (http://www.catlbattery.com/en/web/index.php/about/status).

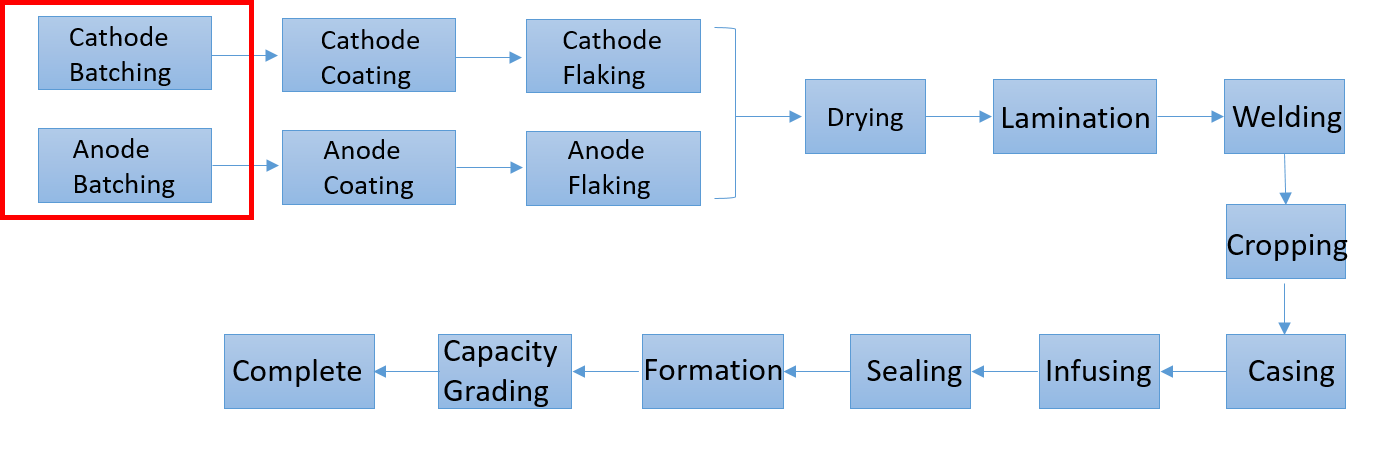

Since 2018, the lithium battery production line of CATL began to use General Measure’s field-bus indicator GM8802-PN and GM8802-EIP for batching of lithium battery ingredients at the front-end (positive and negative) (Figure 1). This is the first step in the production process of lithium batteries. The accuracy of the batching ratio directly affects the quality and performance of lithium battery’s production. Different types of lithium battery have different raw material formulas. In this case, one indicator controls one material, batching based on the accurate weight formula. For instance, several kinds of lithium battery materials (positive electrode: lithium iron phosphate, ternary, LiCoO, LMO, lithium carbonate; negative electrode: graphite, LTO, etc.) are proportioned according to a certain ratio, which the precision is controlled at 1/1000, to ensure the best performance of the lithium battery’s production.

|

|

Figure 1:The Process of Lithium Battery Production |

Application of field-bus Indicator

There are two main installation methods for field-bus indicator in application: equipment field installation and central control room installation. CATL mainly uses on-site installation to facilitate on-site weight monitoring and troubleshooting. Currently, there are at least 500 General Measure’s indicator operated with stably performance on CATL's lithium battery production line.

By converting the analog signal of the sensor into a digital signal, and performing data processing (filtering, shaping), the weight data is truly and stably uploaded to a control component such as a PLC through a field-bus communication method such as Profinet/Ethernet. Then PLC is capable to perform logic control according to the weight data, which ensures high precision and high speed of the ingredients batching of the lithium battery.

|

|

Advantage:

l High Precision: 1/100000, fast communication

l Superior and Stable Performance, Repair Rate lower than0.1%

Due to its superiority of high precision and high speed, such application of field-bus indicator will gradually replace traditional serial communication and analog applications in the food industry, new energy, rubber and plastics industries.